Permacore

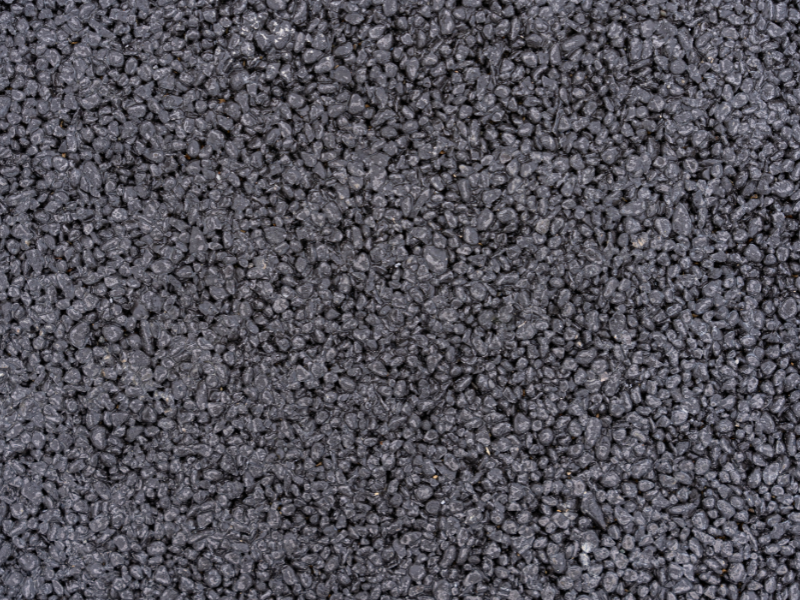

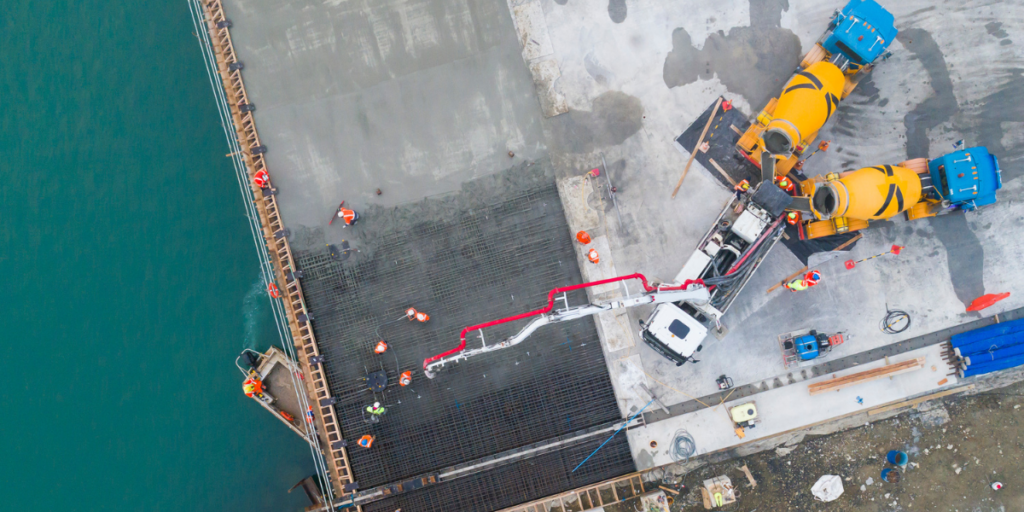

Gallery

Frequently asked questions

What is Permeable Concrete?

Permeable concrete is a specially designed no‑fines mix that allows water to pass through its highly interconnected voids, providing sustainable drainage and reducing storm‑water runoff compared with standard concrete.

How does Permeable Concrete help with storm‑water management?

By allowing rainfall to infiltrate the ground, permeable concrete limits surface ponding, reduces peak‑flow volumes entering council infrastructure, and assists with groundwater recharge. This can defer the need for costly detention tanks or enlarged pipes.

Where can Permeable Concrete be used in New Zealand?

Typical applications include footpaths, retaining walls, cycleways, car‑park stalls, driveways, patio areas, and tree surrounds. Contact our team to receive advice on your project.

What maintenance does Permeable Concrete require?

Routine sweeping and occasional low‑pressure water blasting keep voids clear of silt and organic debris. For high‑traffic zones, annual vacuum‑suction cleaning is recommended.

How durable is Permeable Concrete compared to standard concrete?

When correctly designed and maintained, permeable concrete offers comparable service life in low‑speed environments. Its compressive strength (10-15 MPa) suits light‑vehicle, pedestrian and landscaping loads.

Is Permeable Concrete compliant with local council requirements?

Allied Concrete designs mixes that meet regional water‑quality objectives and relevant NZS 3104 performance criteria. Our team can provide test certificates and design support for building‑consent submissions.